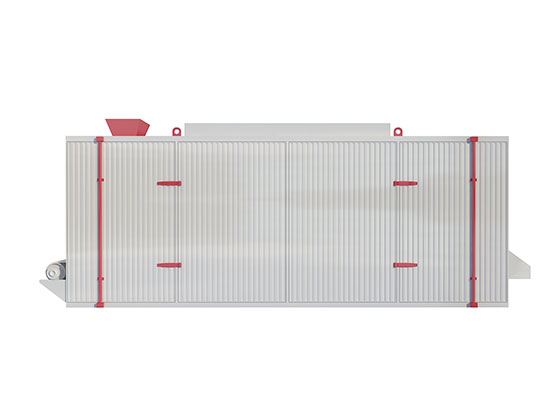

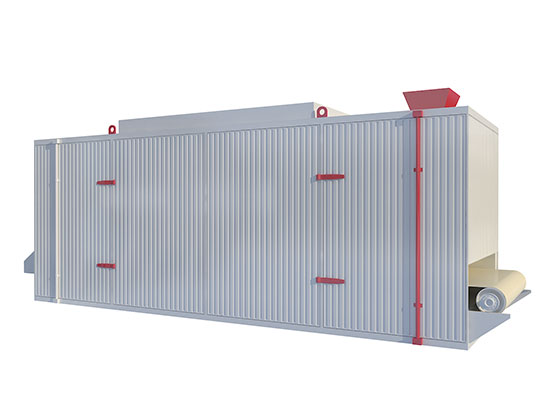

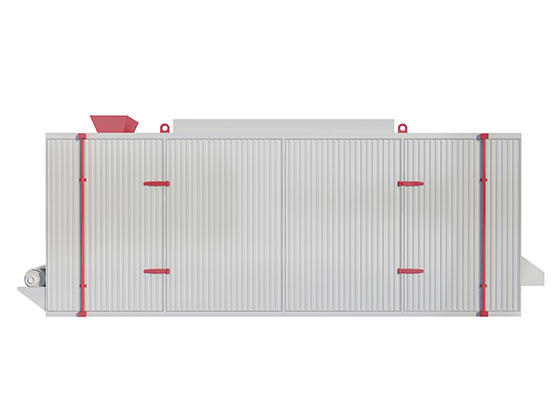

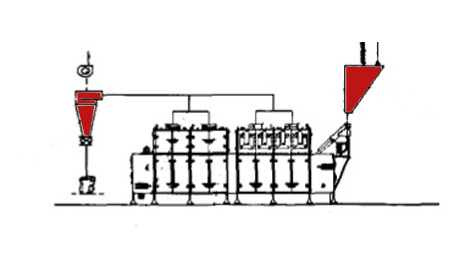

Feed Drying Machine adopts multi-layer belt dryer, which is a batch and continuous production drying equipment. Feed Drying Machine main heating methods are coal-fired heating, electric heating, steam heating and hot air heating. Feed Drying Machine main principle is to evenly spread the material on the conveyor belt, using a conveyor belt with a hole diameter of 3mm-8mm, and dragging and moving in the dryer by the transmission device, the hot air flows through the material, and the water vapor is discharged from the water. The holes are discharged to achieve the purpose of drying. The length of the box is composed of standard sections. In order to save the space, the dryer can be made into a multi-layer type, and the commonly used layers are 3, 5 and 7 layers. Suitable for drying in many industries and various materials, such as food, vegetables, feed, chemical raw materials, decoration materials, medicinal materials, etc.

Purpose of drying:

Improve the stability of the feed. Extend the storage period of the product; promote the change of physical properties of the pellet feed (such as hardness, taste and density); reduce the viscosity of the material, facilitate the processing of the subsequent process; reduce the moisture content; prevent the growth of microorganisms and Toxin production.

1 drying mechanism

The internal moisture of the pellet feed can be divided into combined water and non-bound water. The moisture is evenly distributed in the pellet feed at the beginning. Due to the vaporization of the surface moisture of the pellet feed, the moisture content inside the surface of the crucible is poor, due to the diffusion of moisture inside the pellet. Moving to the surface and vaporizing on the surface, the vaporized moisture is carried away by the drying medium in time to achieve the purpose of drying.

2 drying process classification

The pellet feed drying process is a combination of heat transfer and mass transfer. According to the way that heat energy is transmitted to the wet material, the dryness is divided into conduction drying, convection drying, radiation drying and joint drying.