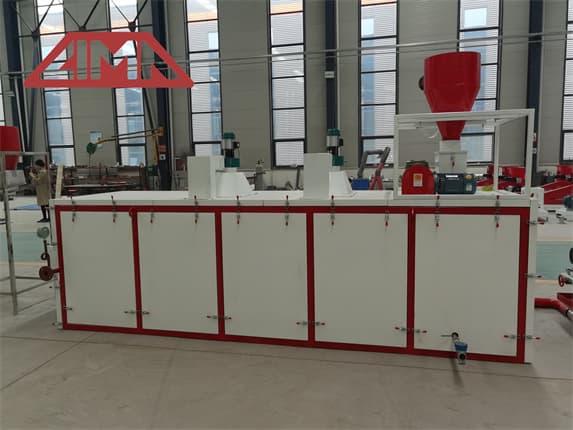

Fish feed dryer machine,animal feed pellet drying machine

Fish feed dryer machine is usually used in combination with fish feed extruder in the fish feed pellet line. Fish feed pellets are transported by the conveyor from fish feed extruder to the pellet dryer machine, then it will be drying on the mesh belt which is made of stainless steel.

Pellets from extruder may content moisture around 15~20% with high temperature, if the user wanna pack fish feed pellet for proper storage and marketing handling. Those pellets must be cooled and dried.

Fish feed dryer machine is movable with multi-layer structure, which makes our dryer fast-drying and high-efficiency. This pellet dryer machine is widely applied in dry granular materials and pellets, like chemical, food, medicine, building materials, electronics and other industries.

Applications

Drying animal feed pellet ,granule

Drying field crops for animal feed industry

Drying of animal, feed and poultry wastes and renderings

Drying fruit and vegetable wastes for animal feed industry

Drying agricultural products and by-products, such as potatoes, cassava and bagasse

Drying of cereals, like rice, beans, for the food processing industry

Features of Animal feed pellet drying machine

1. The animal feed drying machine configuration is very flexible. Simple structure, easy installation and maintenance.

2. Materials will not be vibrated or impacted during the drying process, so the pellets will keep good shape and quality on market.

3. Adjust air quantity and heating temperature, materials staying time and feeding speed can be adjusted to achieve the best drying effect.

4. Hot air can be circularly applied, with fast drying speed, high evaporation intensity, which can save energy greatly.

5. The machine can produce hot air distribute uniformly because its unique air dividing device, this can guarantee finished pellet¡¯s quality.

6. Standardized production, users can increase the number of segments according to production

7. Convenient drying parameters adjustment, flexible operation, it’s widely adaptation, ideal for drying feed pellets, grains and etc.

8. The equipment can produce quality standards of dried foods is more consistent because of these expanded storage, transport and handling possibilities, it makes reliable and continuous provision of superior feed possible, most feed plant has match this fish feed dryer machine.

Working principle of Fish Feed Dryer Machine

Mesh belt type fish feed dryer is a machine for continuous production. It is consist of circulating fan, heating device, fresh-air-suction-system and exhaust-exiting system. Materials evenly spread on the mesh belt by the feeder. The transmission device drag mesh belt moving evenly. The hot air passes through the mesh-belt covered with a special moisture from the top to the bottom or from the bottom to the top, and this will complete the heat and mass transfer process. The air pipe of the top is connected with fan. One part of air is circulated, some exhausted gas is discharged with a special moisture elimination blower, and other waste gas is controlled through an adjustment valve. The top and low circulation units can be freely equipped according to the users demand. The temperature, humidity and exhaust gas re-circulation rate can be adjusted by operator independently, which ensures the reliability of the fish feed pellet dryer, and the optimization of the operating conditions. Heating exchange is sufficient & uniform, drying efficiency being extremely high.