The ring mold pellet feeder (also known as the ring mold pellet machine) is a pelletizing device for feed. It is a

feed processing machine that directly compresses crushed materials such as corn, soybean meal, straw, grass, and rice husk into pellets. It is widely used in large, medium and small aquaculture, grain and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants.

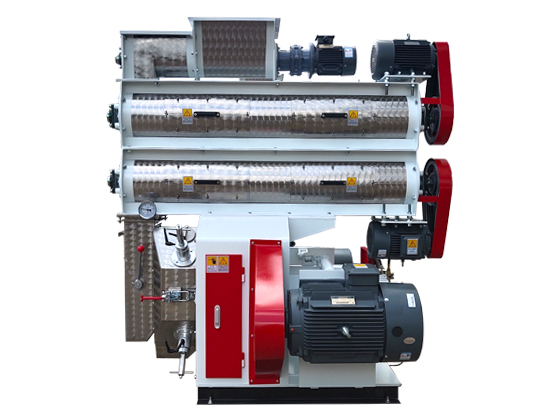

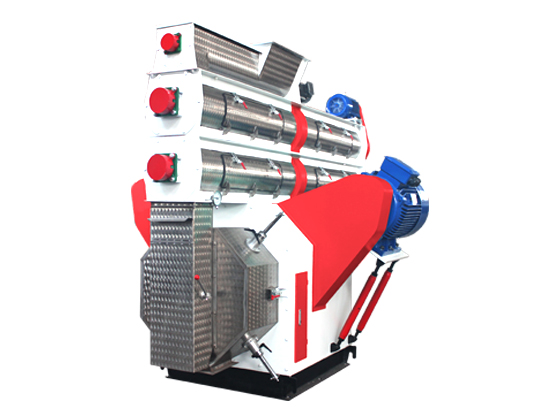

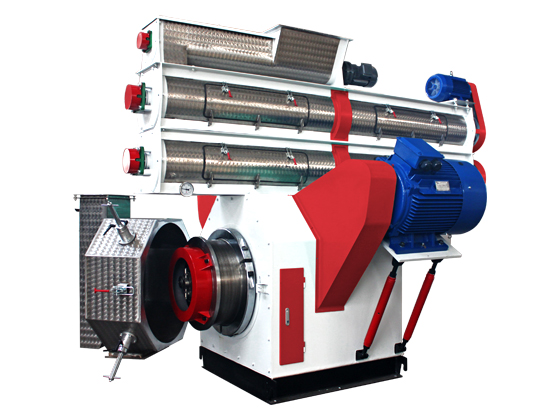

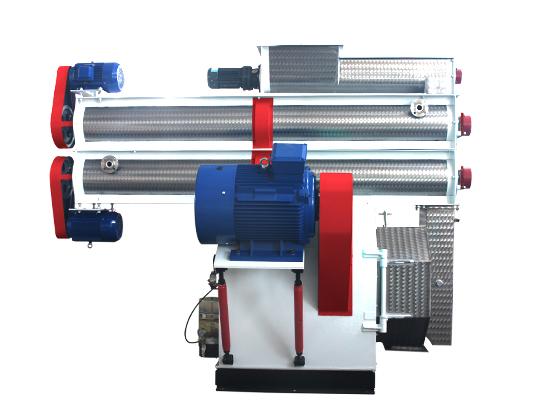

How is Lima Ring-die Feed Pellet Mill Mainly StructuredThis animal feed pellet machine is mainly structured with feeding device, hardening and tempering device, conditioner device, press chamber transmission system, overload protection and electric control system.

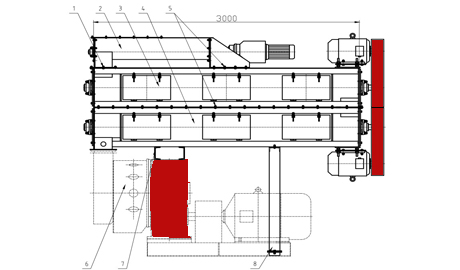

1. Bolt 2. Feeder 3. Upper modulator 4. Lower modulator 5. Bolt 6. Granulator 7. Fixed groove 8. Support frame

How the ring die granulator worksIn the hard

chicken pellet feed line, the ring die granulator is one of the key equipment.

Feed from the state of the powder to the formation of the granules is done in four areas:

1. The material is fed into the conditioner through the speed-adjusting feeding auger. In order to obtain the best granulation benefit (improving the yield and quality), after adding water or steam for quenching and tempering, the chute-shaped cutting tube is passed through the ring mold. The cover, by means of gravity and the centrifugal force generated by the rotation of the ring mold, makes the material close to the ring mold cover and the ring mold wall (feeding area).

2. Under the action of the feeding scraper, the material is uniformly and continuously fed, and the wedge-shaped space (pressing zone) formed by each pressing roller and the ring die.

3. Because the gap between the working surface of the outer wall of the pressure roller and the inner diameter of the ring die is only 0.1mm~0.3mm and the gap is basically constant, a certain pressing force (extrusion zone) is formed.

4. Due to the feeding of the material and the strong pressing between the die and the roller, after the material is compacted, it is extruded into the die hole and formed into a forming zone in the die hole. The material is continuously fed into the pressing zone and extruded, continuously extruded from the die hole, and cut by a cutting knife that can adjust the distance between the blade and the outer wall of the ring die (cut into various required particle lengths). Also available - a special cutter, close to the outer wall of the ring mold, by the amount of feed to control the length of the particles. The length of the particles is 1.5 to 2.0 times the diameter.