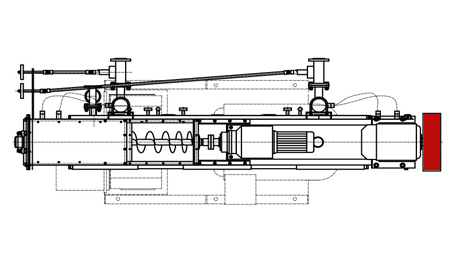

1. Varied driving power, electricity or diesel; environmentally friendly and energy saving.

2. Made of wear-resistant material thus having a long service life.

3. Can make different feed pellets to meet different production requirements.

4. Adjustable compression rate, the flat die pellet mill can meet different pelletizing requirements and is available to press coarse materials.

5. The pelletizing process is visible, so it is convenient to solve problems in time.

6. Simple structure, low consumption, small area coverage, easy operation and maintenance.

7.Feed size can be adjusted according to grinding tool size.