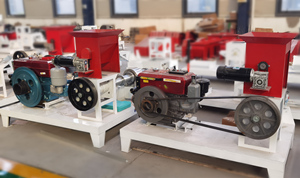

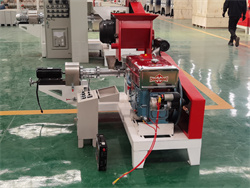

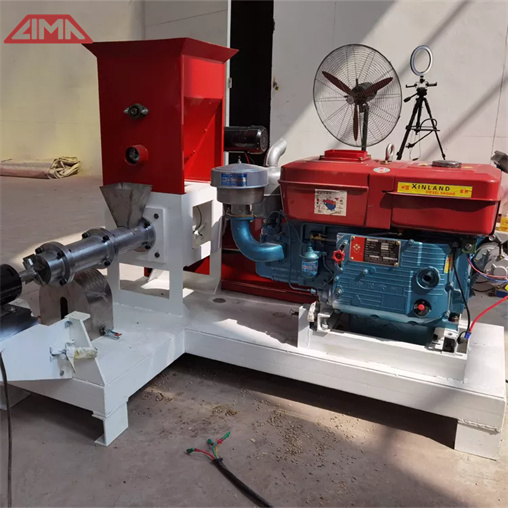

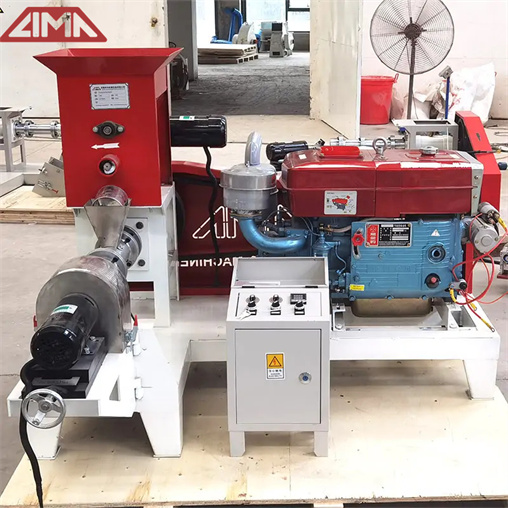

Diesel feed mixer machine,cattle feed mixing machine for sale

Cattle feed mixing machine are used for the mixing of feed ingredients and premixes in feed production plant. The efficient mixing being the key to good feed production.If feed is not mixed properly, ingredients and nutrients will not be properly distributed when it comes time to extrude and pelletize the feed, or if the feed is to be used as mash. This means that not only would the feed not have balance nutritional, it would be bad for the animals that are eating it.So mixer plays a vital rolem in the feed production process .

Structure of Cattle Feed Mixing Machine Feed mixer machine consists of a U-shaped horizontal bucket and a specially fabricated ribbon agitator. The agitator rotates with minimum wall clearance in a U-shaped vessel. A ribbon agitator consists of an inner and outer ribbon which effects a counter flow mass movement with random motion in radial and axial directions: the outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate and moves materials both radially and laterally to insure thorough blends in short cycle times. You can also go to see the small fish feed pellet machine.

Why do you need feed mixer machine in your small feed pellet plant? In past, agricultural livestock production is lagging in efficiency thus resulting in low production output . Mixing can improve the uniformity of particle sizes form hammer mill to keep them in the same particle hardness, which directly improve product quality. The feed mixing is a process that a variety of feed raw materials after measured, are blended under external force to be evenly distributed.

It is well suited for the preprocessing of feed mixture for making livestock, poultry and fish feed pellets.The feed mixer is to ensure that the poultry and livestock can obtain all the necessary nutrients in every meal, in case animals only eat a part of feed ingredients. Therefore, feed mixer ensures uniform distribution of each component in the bulk material feed, especially those “active ingredients; which are added a very small amount but has great influence on animal growth and are required to be evenly distributed, such as vitamins, microelements, medicaments and other microconstituents, etc.In animal feed production, feed mixer working conditions not only determines the quality of the feed product, but also determines the production capacity of the whole feed production plant. So feed mixer is called the heart of a feed mill plant.

Therefore cattle feed mixing machine is the critical equipment in cattle feed pellet production. Zeno pellet machine provide ribbon type feed mixer machine is mainly applied to mix powdery feed materials to ensure a high quality of compound feed. And it is a well-performed feed mixer for livestock and other animal feed pellet production line like floating fish feed production line.

Features of Cattle Feed Mixing Machine

1.High homogeneity: This kind of diesel feed mixer machine design reinforces convection, shearing, and mixing effects.To distribute materials with different characteristics as evenly as possible.

2. Human friendly: Simple and reasonable structure, convenient maintenance, reliable, safe, effective and less investment. The mixer also can be equipped with jacket to facility heating and cooling materials. At the same time, thermal insulation materials also can be installed as required.

3. Multiple application: It can be used for mixing feed, food additives, binder, silicone rubber, pigment, printing ink, paraffin, resin, etc; and also can be used for mixing viscous fluid and thick, pasty and granular materials.Adding liquid in the mixing powder to prepare for decreasing the hardness of feed pellets.

4. Quick feed and discharge, little residue, which can meet the needs of adding the liquid.