Every part of fish feed production line:

1. Flour mixing machine: Add a certain proportion of water to the raw materials such as corn flour, rice flour, soybean flour, meat flour, cereal flour, additives, etc., and mix well.

2.Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

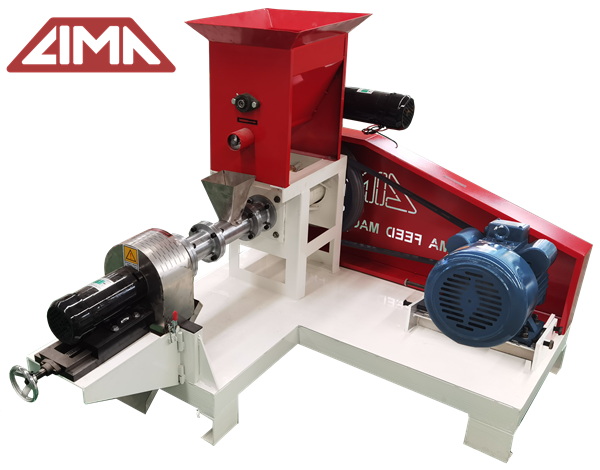

3.Twin-screw extruder: Under the conditions of high temperature and high pressure environment and screw extrusion, the die can be changed by adjusting the different feeds of the production department of the process, the specific particle size and shape.

4.Conveyor: convey the feed to the oven.

5.Seasoning line: the oil sprayer sprays oil, phagostimulants, etc. The seasoning tube includes octagonal tube, cylinder, lifting single drum, double drum seasoning line, according to the output and product nature configuration, spraying grease on the surface of the feed, and at the same time Spray minced meat and spices evenly.

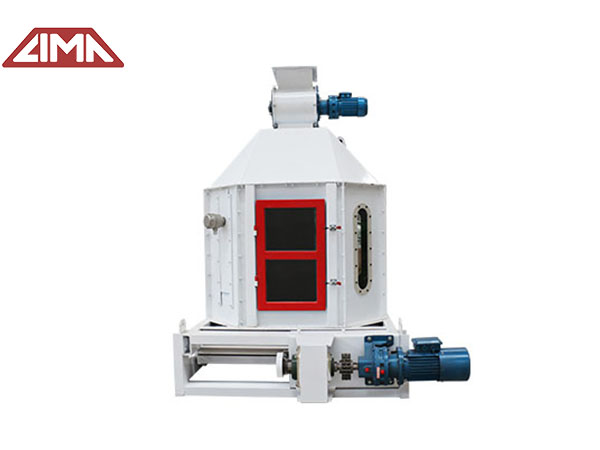

6.Cooling and conveying: reduce the temperature of frying and feed, promote the solidification of fat, reduce the temperature of particles, and facilitate packaging.

7.Vibrating sieve: sift out the excess sprinkled materials and particles at the end of the year to ensure the quality and the reuse of raw materials.

8.Packaging machine: manual sealing machine and automatic packaging machine can be used.

Welcome to see the fish feed pellet production line in Lima.