Factory use poultry feed pellet making machine line

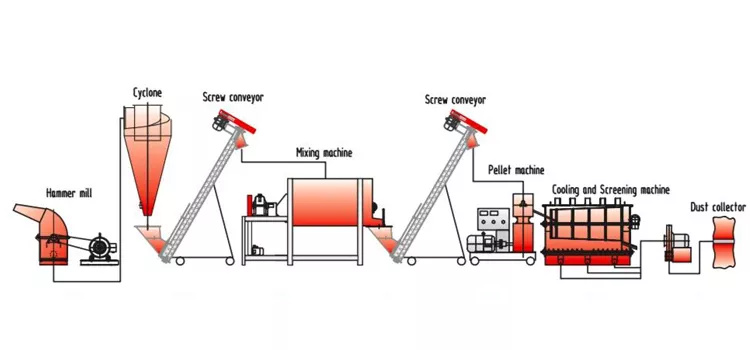

This poultry feed pellet making machine line of this design is the best-selling of LIMA Company, popular in animal feed manufacturers, it contains crusher, cyclone, screw conveyors, mixer, pellet machine, cooler and dust collect. The generally recommended capacity of this poultry feed production line is 500kg per hour, and this poultry feed pellet making machine can produce animal feed such as chicken, duck, geese, pig, cattle and sheep, so it is suitable for all investors who want to do feed production business.

In the poultry feed production line, what are the wear parts? How to perform daily maintenance?

In the normal operation of the machine, there will always be machine parts that are depreciated due to the operation and need to be replaced when due. But if you maintain these parts on a routine basis, they can extend their life and save you money on replacement parts. So, where are these parts? And how to maintain it? I will tell you below.

Where are these parts?

The first is in the pulverizer. When the pulverizer works, it needs to rely on the cutter or hammer inside to crush the granular raw materials. After working for a long time, the cutter or hammer will definitely be damaged.

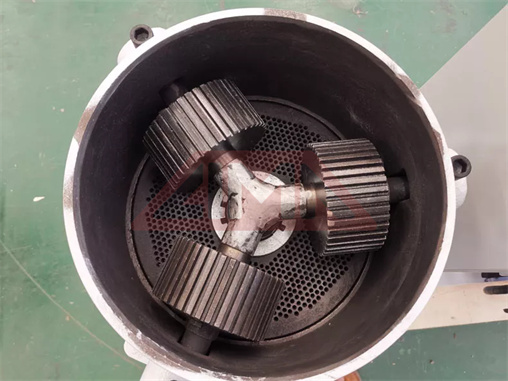

The second place is in the pellet machine. The grinding disc and roller in the granulator squeeze the raw materials when the machine is working, so this is also the wear area of the machine.

So how to carry out daily maintenance?

First of all, after the machine is finished working each time, these two places are cleaned and dried.

Secondly, it is necessary to avoid hard objects such as stones in the raw materials.