Ring die pellet mill for sale,commercial feed pellet machine

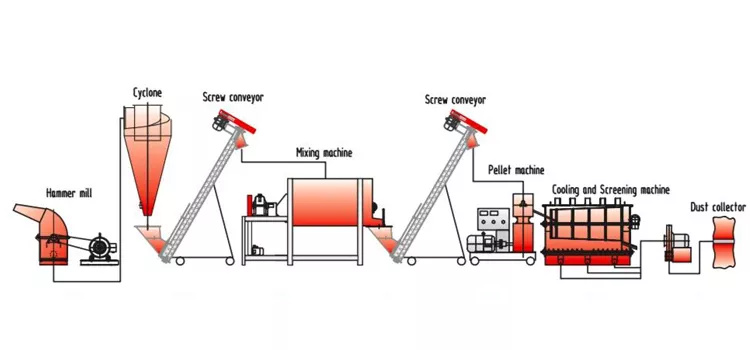

Ring die pellet mill adopts mature technology to produce high-quality animal feed pellets for cattle,cows,horses,chickens, and ducks on a large scale. The ring die feed pellet machine has become more and more popular on the market for its outstanding characteristics of high output, low consumption and mature technology,and has a broad market share in the industry. It is ideal equipment for raising livestock and poultry such as feed pellet plant, livestock ranches, poultry farms,medium and large feed processing industries.

Pelleting is a key to the production of high quality nutrition feeds as they ensure that the feed formulation is in the correct quantities for all that eat them.Each pellet will have the same designed formulation ensuring all the stock are feed as intended.The pelleting process is forcing soft feed materials through holes in a metal die plate to form compacted pellets which are then cut to a pre-determined size. The machinery which has been developed for this purpose is now very diverse in design ,and different animals need different size of pellet.

Multi-aperture ring mold can meet user’s requirement,they can get different size pellet according to change ring die .Those ring mold adopted excellent technology, long service life, the production of smooth, high-quality feed particles.

The compression ratio can be selected according to the raw material formula and product requirements,it can be adjusted by ring mold of the ring die pellet mill. Low compression ratio can increase output, reduce energy consumption and reduce the wear of ring die pellet mill spare parts. But the pellets will be loose,the feed pulverization rate will be high and the length of the pellets are hard to control.On the other hand, if the user using high compression ratio, the pellets will be strong, smooth and glossy, low broken rate .But the production cost will be high and machine consumption will be high.

Structure of Ring Die Pellet MillRing die pellet mill using a ring type die turning about two fixed rollers, with the die and rollers mounted in a vertical plane.

A few mills are built with the dies and rollers in a horizontal plane with the rollers turning within the stationary die. Obviously there are advantages to each type of machine but more mills are made of the vertical type nowadays.The conditioned mash is forced through holes in the die by roller pressure in the pelleting unit.Die thickness is mian factor in the production of high quality pellets and it must be accurately balanced with the formulation and conditioning. Since die speeds are always less than the conventional motor speeds ,that why all pellet mills incorporate speed reduction device.Ring die pellet machine have one or tow conditioned mounted above them where liquids such as water and molasses can be added to improve pelletability. The water is added in the form of steam which softens the feed and partially gelatinises the starch content of the ingredients, resulting in firmer pellets.

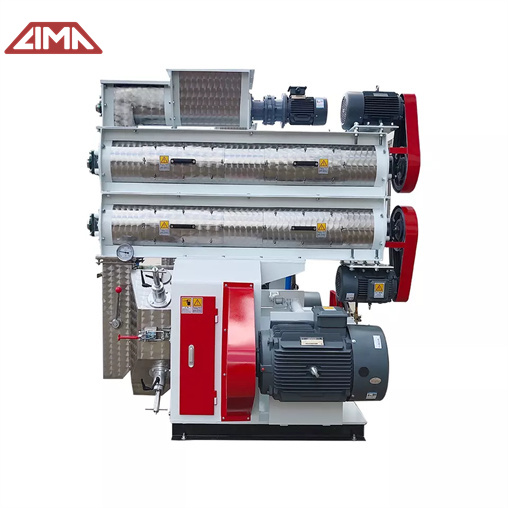

Features of Ring Die Pellet Mill

¡ô The feed pellet mill is equipped with stainless steel feeder and imported inverter contorl to guarantee accurate and stable raw material feeding.

¡ô The user can choice normal conditioner or stainless steel conditioner.For stainless steel condition, we are using food grade 304 stainless steel paddles and paddle shaft , which can guarantee the livestock and poultry feed pellets safety. The user also can choice single-conditioner or double-conditioner feed pellet mill. Double-conditioner pellet can make better pellets with higher price than single type.

¡ô Ring die pellet mills adopt dual-motor V-belt drive system to achieve stable transmission, high driving torque,main shaft long service life, steady transimmison, easy maintenance and low maintenance cost for the user.

¡ô Commercial feed pellet mill adopts automatic grease adding system,the support sleeve of main shaft and main case is lined with brass bush to prevent occlusion and is easy to dissassembly.

¡ô The sealing performance of the ring die pellet mill is much better than that of the flat die type. There will be no particularly big dust when machine working .Compared with flat die pellet machine, the ring die feed pellet mill is more effective and suitable for mass production of animal feed pellets.